US-Made Solar Energy Deliver Benefits Far Beyond Clean Energy

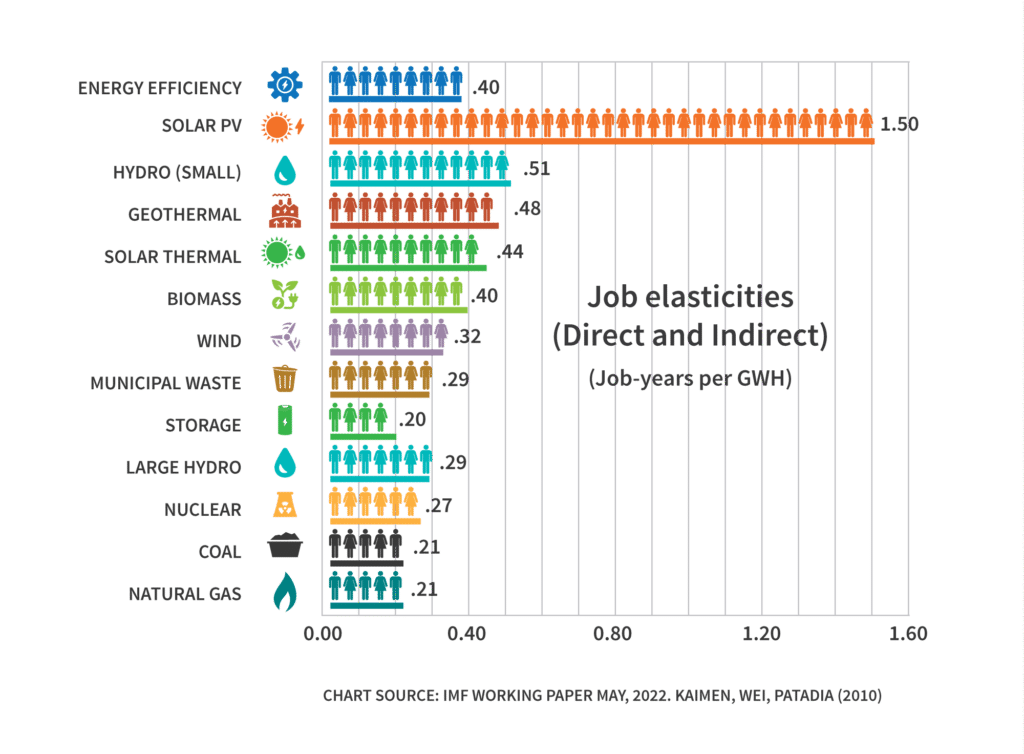

Investing in solar energy contributes significantly to growing a clean economy with benefits to customers, communities, and investors. In the electricity sector, solar can create the most jobs per watt of any energy source.

Not only are solar power jobs numerous compared to other energy sources, but these jobs also pay well. Research by a collective of organizations including the American Council on Renewable Energy finds that clean energy jobs overall provide a median hourly wage of $23.89. This is 25% higher than the national median wage of $19.14. More specifically, the solar industry supports even higher wages at $24.48. In fact, all clean energy sectors support above-average wages when compared to the national median hourly wage. This is an amazing outcome given that solar is also now one of the least expensive forms of electricity available!

Community Economic Benefits from Expanding Solar Manufacturing in the USA

For Silfab Solar, being a locally headquartered manufacturer supplying the North American solar customer base is a priority. The company’s manufacturing facilities are in Burlington, Washington, and Fort Mill, South Carolina. The Fort Mill facility is our newest and will be both a solar cell and panel manufacturing plant. It will be one of only three solar cell plants in the US and will manufacture the most efficient type of cells available in the world – N-type.

Solar energy not only creates the most jobs for any energy source, it also generates clean energy that helps mitigate climate change, reduces other air pollution that can create health risks, and helps save customers money by enabling them to generate their own electricity. A contributor to this environmental success story is that locally made solar has a lower carbon footprint due to North America’s cleaner electricity grid and strong regulations. This helps reduce our impact on the environment and create more resilient communities. Additional environmental and economic benefits are created when we bring our supply chains closer to home as they create jobs, reduce transportation impacts and lift local economies. For our company these are important priorities, as we see value in being good neighbors in the communities where our employees and suppliers live.

To Silfab, all these factors combine to create a virtuous positive energy loop from solar, supporting the US economy in so many ways.

Silfab Solar is directly engaged in the US policy landscape regarding reshoring solar manufacturing and creating an equitable competitive landscape for solar products. With expansion into cell production, Silfab Solar is well-positioned to meet the US’s expanding demand for domestically made high-quality solar products and support the goals to increase the percentage of American-made components in solar modules.

Silfab Solar’s cell and PV module manufacturing plant in South Carolina represents the next step in our investment in deeper vertical integration of solar manufacturing, which will result in competitive, financial, social, and environmental benefits. South Carolina is an attractive location as it is one of the US states where solar manufacturing is supported by a government active in developing local, sustainable industries. Access to low-carbon energy was also a key factor in our decision to establish this location as it will enable us to make our solar products even more sustainable.

The new facility will add 1GW of American-made solar cell production and another 1.3GW of PV module production. We are committed to providing 800 new skilled jobs, $17 million in property taxes to local schools, $4.7 million taxes to York County, and an estimated annual payroll of more than $48 million.

Hand in hand with the new solar cell manufacturing investment, Silfab Solar has been selected for an innovation award by the U.S. Department of Energy to continue its objective of becoming a national leader in USA-produced, next-generation solar cells. The $20 million project will develop back-contact N-type cells to demonstrate efficiencies of 26% or better. The Silfab Solar R&D team is developing this innovation on a 300MW pilot line, which will operate alongside Silfab Solar’s main N-type cell manufacturing at our new South Carolina facility. The project will enable rapid scale-up of cost effective, back-contact cell technology into high-volume manufacturing of Silfab Solar’s next line of premium PV solar modules.

As part of the federal government’s Solar Energy Technologies Office (SETO) program to provide community benefits in project locations, Silfab Solar has begun a series of workforce development initiatives and school outreach programs to encourage youth to consider careers in renewable energy, among other efforts.

Sources: