WHO WE ARE

Silfab Solar is an American leader in the design, development, and manufacture of high-efficiency, premium-quality solar cells and modules. Silfab leverages more than 40 years of solar industry experience and best-in-class technologies to produce the highest-rated solar products. With locations in Burlington, Washington, Fort Mill, South Carolina, and Toronto, Canada, all our operating locations feature fully automated production lines and are certified to the ISO 9001:2025 Quality Management System Standards.

BRINGING SOLAR PRODUCT ASSEMBLY BACK HOME

Our Fort Mill plant will help to reshore solar cell design and assembly back to the US, driving innovation and domestic jobs, and ensuring an American-made supply chain to help deliver our nation's energy needs. We are putting America first.

OUR INVESTMENT WILL Generate

800

New American Skilled Jobs

$4.7M

Property taxes for York County

$17M

Property taxes for Fort Mill School District

EXPERIENCE

Silfab leverages more than 40 years of solar experience and best-in-class technologies to produce the highest-rated solar cells and panels. We operate our facilities in the US with a commitment to safety, sustainability, and environmental responsibility.

JOBS & EDUCATION

Our plant brings over 800 high-paying new jobs directly to York County, providing on-the-job skills training and career development opportunities. We are committed to the well-being of our South Carolina employees.

AMERICAN ENERGY INDEPENDENCE

In the coming years, America's appetite for energy will grow exponentially as the population, AI, and data centers expand. Silfab is proud to support this need with American-made, high-efficiency solar panels.

POSITIVE ECONOMIC GROWTH

By locating in York County, Silfab is bringing $17M in property taxes for Fort Mill School District and $4.7M in property taxes for York County. Working hand in hand with the county, we are excited to spur new economic opportunities for small businesses and other partners who support our operations.

ANSWERS TO YOUR QUESTIONS

Silfab understands there are questions circulating in the community about our plant. We are happy to answer some of the most frequently asked questions.

BUILDING A BRIGHTER FUTURE

Silfab Solar is committed to making a difference in the communities where we live and operate. Through a range of initiatives, we support local and global organizations, advance sustainability, and invest in education to help build a brighter, more equitable future.

COMMUNITY PARTNERSHIPS

Silfab Solar partners with local, national, and international organizations to support food banks, groups, and protect wildlife habitats through volunteer efforts and donations to create and build stronger communities. By investing in people as well as clean energy, we help communities thrive today while shaping a more sustainable future for generations to come.

SUSTAINABILITY EFFORTS

Silfab Solar takes sustainability seriously across our entire operations, from repurposing plastic pallets and barrels to donating reusable bags, implementing internal sustainability programs, and volunteering in community cleanups. Silfab also has a robust recycling program for non-useable solar panels and manufacturing waste. We remain focused on reducing waste, optimizing energy use, and advancing a circular solar supply chain that delivers meaningful environmental outcomes.

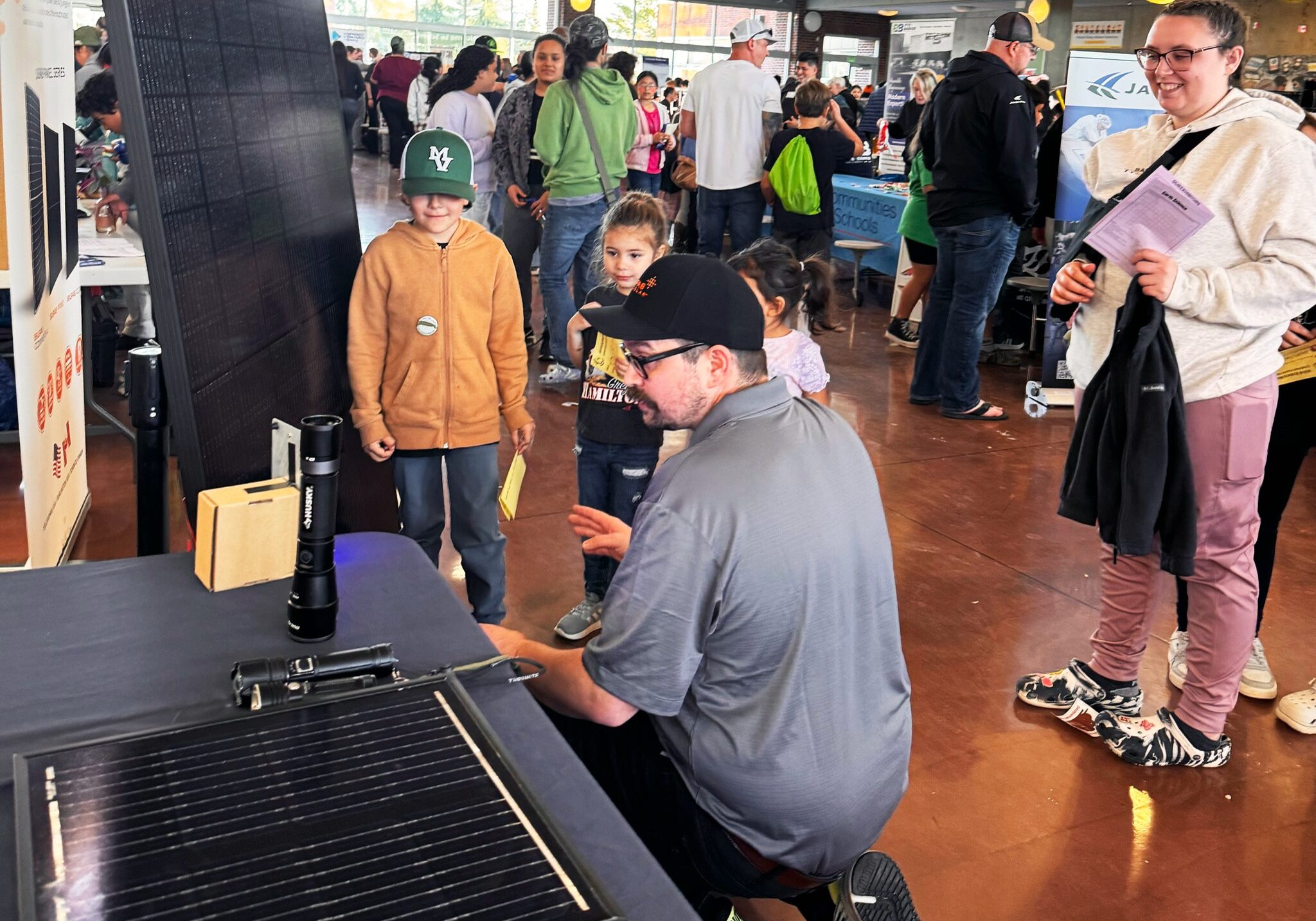

EDUCATIONAL SUPPORT

Empowering the next generation of innovators, Silfab Solar invests in programs that inspire careers in STEM, environmental science, and renewable energy fields. Through partnerships with local schools, universities, and community organizations, we provide mentorship, internships, and scholarships, and hands-on opportunities that help students to shape a cleaner, brighter future.

News & Updates

Silfab notified employees and community leaders earlier today of the decision to voluntarily pause operations for the remainder […]

Read More -Regarding the letter Silfab Solar received today from the Department of Environmental Services, the Silfab technical response team […]

Read More -With no danger to public safety, Silfab Solar can confirm the accidental release of no more than 300 […]

Read More -Have more questions?

If you have a general question or need information as a homeowner or installer on where to buy Silfab Solar panels in your area, fill out the contact form below, and one of our team members will be happy to assist you.