The Growing Need for Solar Panel Recycling in the U.S.

SOLAR PANEL RECYCLING MATTERS

Every day, hundreds of thousands of solar panels are installed in fields and on rooftops across the United States. In total, hundreds of millions of panels have been installed over the past 20 years.

Some of those older panels are now ready to be replaced, either because they’ve reached the end of their lifespan, or because new, highly efficient models are ready to replace older ones to improve energy yield from large installations.

The ideal way to handle these older panels is to repurpose them if they are usable, or to recover the materials for use in future products. The perfect solar panel lifecycle is circular, meaning that materials in the existing solar panel are recycled and used to make new solar panels.

Silfab Solar works with SOLARCYCLE and other recycling companies to realize our vision of a circular solar value chain, so the materials used in today’s panels will live on for many generations in the future.

THE NEED FOR SOLAR PANEL RECYCLING

Solar panel recycling is becoming an important issue as existing solar panels age, and the scope of the issue will soon grow exponentially.

There are over two terawatts (TW) of solar panels currently installed, and nearly all of them will need to be replaced within the next 25 to 30 years. Recycling these panels can save most of that material from being sent to landfills, returning much of it back into the solar economy.

According to the International Renewable Energy Agency (IRENA), the world could see up to 3.3 billion retired solar panels needing sustainable disposal solutions by 2050. These solar panels will be a very important source of material for making new panels. Research from the National Renewable Energy Laboratory (NREL) suggests that recycled panels and materials could help meet 25-30% of the U.S. domestic solar manufacturing needs by 2040.

To put it mildly, there is a huge opportunity in finding ways to recapture as much material from retired solar panels as possible.

That’s where the SOLARCYCLE partnership comes in. SOLARCYCLE has developed industry-leading recycling technology and forged long-term partnerships with Silfab Solar and more than 90 other leading energy brands to recycle solar panels and recover the materials that go into them.

DELIVERING ON OUR SUSTAINABLE VALUES AND VISION

The partnership between Silfab Solar and SOLARCYCLE is helping to bring about the future of solar materials recovery. Both companies have built circularity into their missions and are committed to creating more opportunities to use recycled materials.

Silfab Solar integrates design for recyclability into manufacturing, making materials easier to recover. We also prioritize supply chain traceability and made a commitment to reduce our carbon footprint by at least 30% by 2026, with a further goal of net zero emissions from our operations by 2040. Details can be found in our latest sustainability impact report.

SOLARCYCLE is America’s most advanced recycler, with a process that keeps e-waste and valuable materials out of the landfill, reinforces the domestic supply chain, reduces carbon emissions though a closed-loop solar ecosystem, and partners with companies to help establish their solar circularity programs.

PRIORITIZING SOLAR PANEL RECYCLING

The partnership between Silfab Solar and SOLARCYCLE enables innovation that will build on current success and continue to expand solar panel recycling.

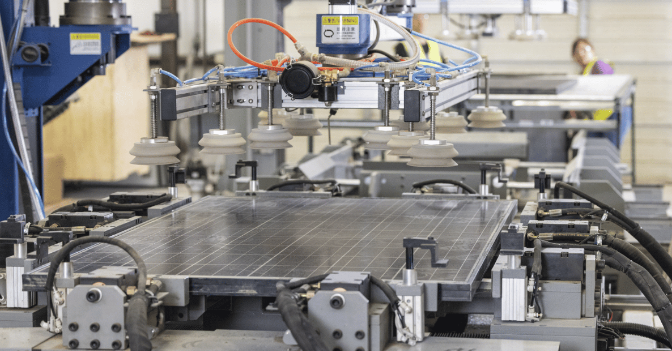

Photo Credit: SOLARCYCLE

SOLARCYCLE has developed methods to extract and purify metals like copper and silicon from end-of-life panels. The company extracts up to 95% of the value in a solar panel and returns it to the domestic supply chain. Material recovery and purity are top priorities for SOLARCYCLE. Every panel sample goes through detailed analysis, so they know exactly what is there — down to the milligram.

HOW SILFAB SOLAR PANELS ARE PROCESSED AND RECYCLED AT SOLARCYCLE FACILITIES

Silfab Solar sends damaged solar panels and manufacturing waste that is ready for recycling to SOLARCYCLE’s facilities where the panels are first evaluated for material identification and processing.

SOLARCYCLE’s advanced recycling technology first removes the aluminum frames and junction boxes. Then panels are sent through the company’s “deglass” machine which cleanly removes the glass from the solar laminate.

In the next step, the laminate (which contains the solar cells, busbars, encapsulant layer and backsheet) is shredded and processed through multi-stage proprietary systems to separate valuable solarMETALS (silver, copper, aluminum) and plastics. These valuable materials can then be reused to make new solar panels and other products. Soon SOLARCYCLE plans to use the recycled glass themselves to make new solar glass at its Georgia solar glass factory, further reducing carbon emissions across the solar supply chain.

Photo Credit: SOLARCYCLE

FINAL THOUGHTS: HOW TO SUPPORT SUSTAINABLE, DOMESTIC MATERIAL SUPPLY FOR THE SOLAR INDUSTRY

Solar panel recycling is incredibly important for today’s solar manufacturing industry and will only become more important as time goes on. Building a circular economy for solar materials will have a profoundly positive impact on the environment, domestic materials supply, and carbon emissions reduction.

These benefits are what drove Silfab Solar to partner with SOLARCYCLE. Working together allows both companies to pursue our shared goals of making the solar supply chain more sustainable.

Every time a homeowner or solar installation company chooses Silfab Solar panels, they are directly supporting solar panel recycling and bringing about a more sustainable, environmentally friendly solar supply chain.